Winckler & Co. is proud to announce that we are attending the IPF Japan 2017.

We will exhibit machines in the categories bottle printing, plastic tube heading, and bottle leak testing.

We are looking forward to seeing you at the IPF Japan 2017. Please contact us to schedule your meeting!

Date: 24 – 28 October 2017

Time: 10:00 – 17:00 (16:00 last day)

Place: Makuhari Messe

Booth no.:81517

IPF Japan 2017 official web site: http://www.ipfjapan.jp/english

Exhibiting manufacturers

OMSO S.p.A. (Reggio Emilia ITALY)

- Bottle screen printing machine SERVOBOTTLE.

AISA Automation Industrielle SA. (Vouvry, Switzerland)

- Plastic tube header PTH 90

ProfileSolutions (Australia)

- Bottle leak tester 6LD

Exhibited machinery

OMSO S.p.A. (Reggio Emilia ITALY)

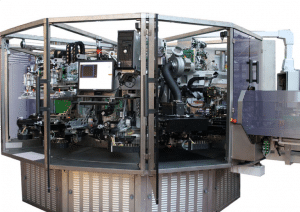

Bottle screen printing machine SERVOBOTTLE.

SERVOBOTTLE is a fully servo-controlled screen printing machine for glass and plastic bottles.

With full servo control and single-chucking handling, the device can achieve a high-level positioning accuracy between colors.

Servo control also enables parameter setting management of print jobs drastically reducing the time required for a job change.

No complicated adjustment using tools is necessary when changing the format.

Once production conditions are saved, even staff with low proficiency in the machine can start production with ease, following a simple procedure.

Movement of the bottle body at the time of printing is also servo-controlled. So, it is possible to decorate 360 ° in one color with an oval bottle or the like.

LED UV is adapted for ink drying, and drastically reduces not only the ozone emission amount but also achieved 80% reduction in power consumption compared to a conventional UV lamp.

AISA Automation Industrielle SA. (Vouvry, Switzerland)

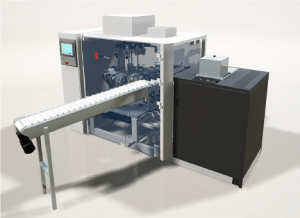

Plastic tube header PTH 90

AISA PTH 90 molds a tube shoulder while extruding it to a laminate sleeve or plastic sleeve (extruded sleeve). It is a molding machine that welds a tube header while molding a shoulder.

This machine makes tube heads and attaches it at the same time. (compression molding technology)

Thanks to excellent cooling efficiency, it is possible to produce at maximum 90 tubes per minute. (depends on resin and diameter.)

The sophisticated component design such as cooling water path for tube shoulder becomes possible by Aisa’s metal 3D printers. This improves the efficiency of shoulder cooling after molding, contributing to the greater production speed and the beauty of the shoulder.

Parameterized molding recipes can be loaded quickly after format changes. It makes it easy for many operators to operate the machine.

Since it has many advanced functions such as production with incomplete objects or using only odd or even mandrels, PTH series is the most preferred and has lots of repeat users.

ProfileSolutions (Australia)

Bottle leak tester 6LD

Profile Solutions’ Leak Tester 6LD detects pin holes in bottle containers of about 30 mL to 6 L.

Maximum capacity is 9,500 bottles/hour with 150 ml capacity.

Pinholes of 0.17 mm can be detected even at high-speed operation, and by extending inspection time, the detector can detect much smaller holes.

Optionally you can add vacuum to the conveyor, making it possible to stabilize the bottle on the conveyor and to speed up the leakage inspection.

The inspection speed and accuracy are among the best in this range of products.

Please feel free to contact us from here about the exhibited machines and the exhibition.