OMSO S.p.A., established in 1952 in Reggio Emilia, Italy, is a global leader in the manufacturing of world-class printing equipment. With the use of highly automated technology OMSO specializes in printing on containers of differing shapes, dimensions and materials for the food, cosmetic and pharmaceutical industries.

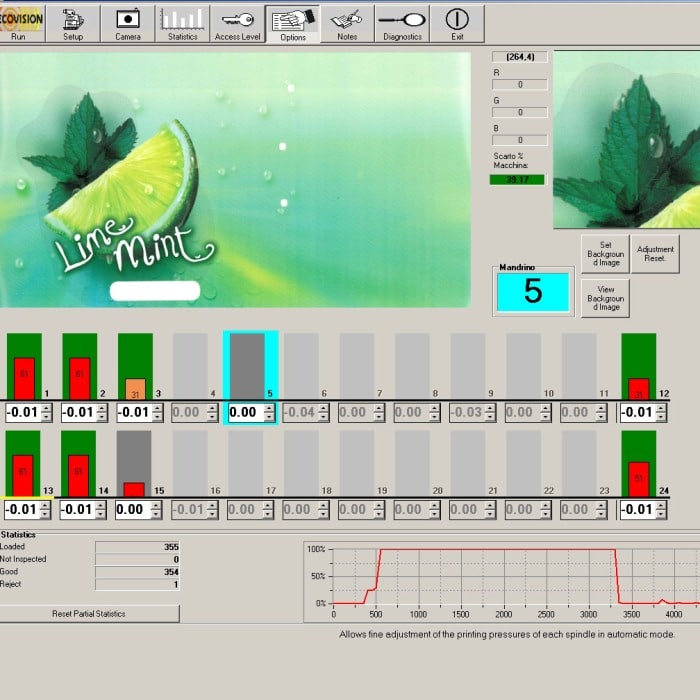

OMSO is able to satisfy an increasing spectrum of deeply diversified decoration needs. From its inception the primary goal has been continuous improvement to direct print quality and graphics capabilities, using innovative technologies in the screen, dry-offset and flexographic printing industry.

Winckler has more than 30-year experience and over 100 installed machines as a representative for OMSO. We can provide a high-level of support and after-service in cooperation with OMSO.