Thank you very much for your continued support.

We are pleased to inform you that at Interpack 2026 (Düsseldorf, Germany), the manufacturers represented by our company will be exhibiting as outlined below.

We understand you may be very busy; however, should you have the opportunity to visit the exhibition, we would be grateful if you could stop by each exhibitor’s booth and view their latest exhibits. Details of the exhibition and each manufacturer’s exhibits are provided below for your reference.

Exhibition Overview

| Exhibition: | Interpack 2026 |

| Dates: | May 7 (Thu) – May 13 (Wed), 2026 |

| Opening hours | 10:00 a.m. – 6:00 p.m. |

| Venue: | Messe Düsseldorf, Germany |

| Venue map: | https://www.interpack.com/en/Interactive_hall_plan |

| Admission: | Please purchase an admission ticket in advance from the official Interpack ticket page before visiting. |

Exhibiting Manufacturer and Machineries

groninger & co. gmbh – Germany

| Hall: | 16 |

| Booth: | B37 |

| Exhibit: | Filling and closing systems for vials, bottles, and syringes |

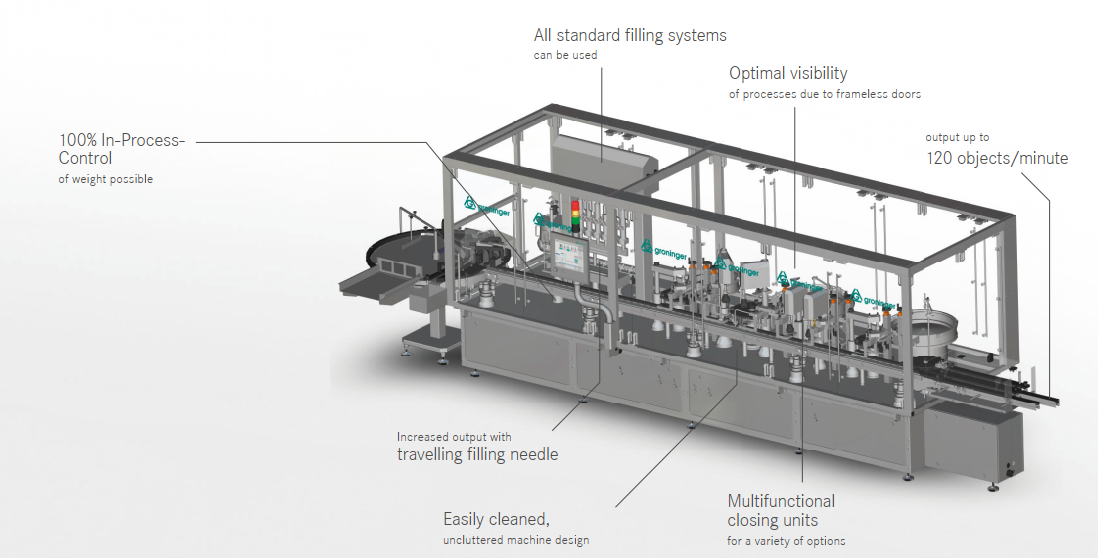

FLEXCARE 100

The slim and LF-friendly machine design consistently complies with GMP requirements, enhanced by optimum accessibility and ease of cleaning.

Customized to your requirements, a wide variety of machine functions can be added to this system, including pre-gassing, gassing during filling and post-gassing, filling, dropper and spray pump insertion, closing and torque-controlled pretorquing and post-torquing with servo-motors.

Maximum flexibility and availability with options such as fast format changeover without tools. The stable transport with walking beam makes it easy to install fully automatic 100% In-Process-Control.

The ease of implementation of batch and audit trail logs simplifies GMP-relevant documentation of production data.

Furthermore, we will mainly focus on the following themes:

- Equipment for aseptic filling and closing

- Equipment for filling and closing eye care products

- Equipment for non-sterile filling and closing

- Equipment for cosmetics

- Service

KORSCH AG / MEDELPHARM

| Hall: | 16 |

| Booth: | A42 |

| Exhibit: | Tablet Presses & Tablet Inspection Systems |

STYL’ONE Evo WipCon (R&D Tablet Compression Simulator)

The STYL’ONE Evo WipCon is capable of reproducing and simulating the compression dynamics of virtually all existing rotary tablet presses.

This makes it an ideal tablet compression simulator for a wide range of applications, from early-stage tablet characterization and formulation development to scale-up studies and troubleshooting on production machines.

The STYL’ONE Evo supports a wide variety of tablet formats, from single-layer up to five-layer tablets, including core tablets. It is compliant with USP <1062> and enables simulation of all parameters required for tablet characterization and formulation development.

The exhibited unit is equipped with an isolator and features a WIP configuration compliant with OEB 5.

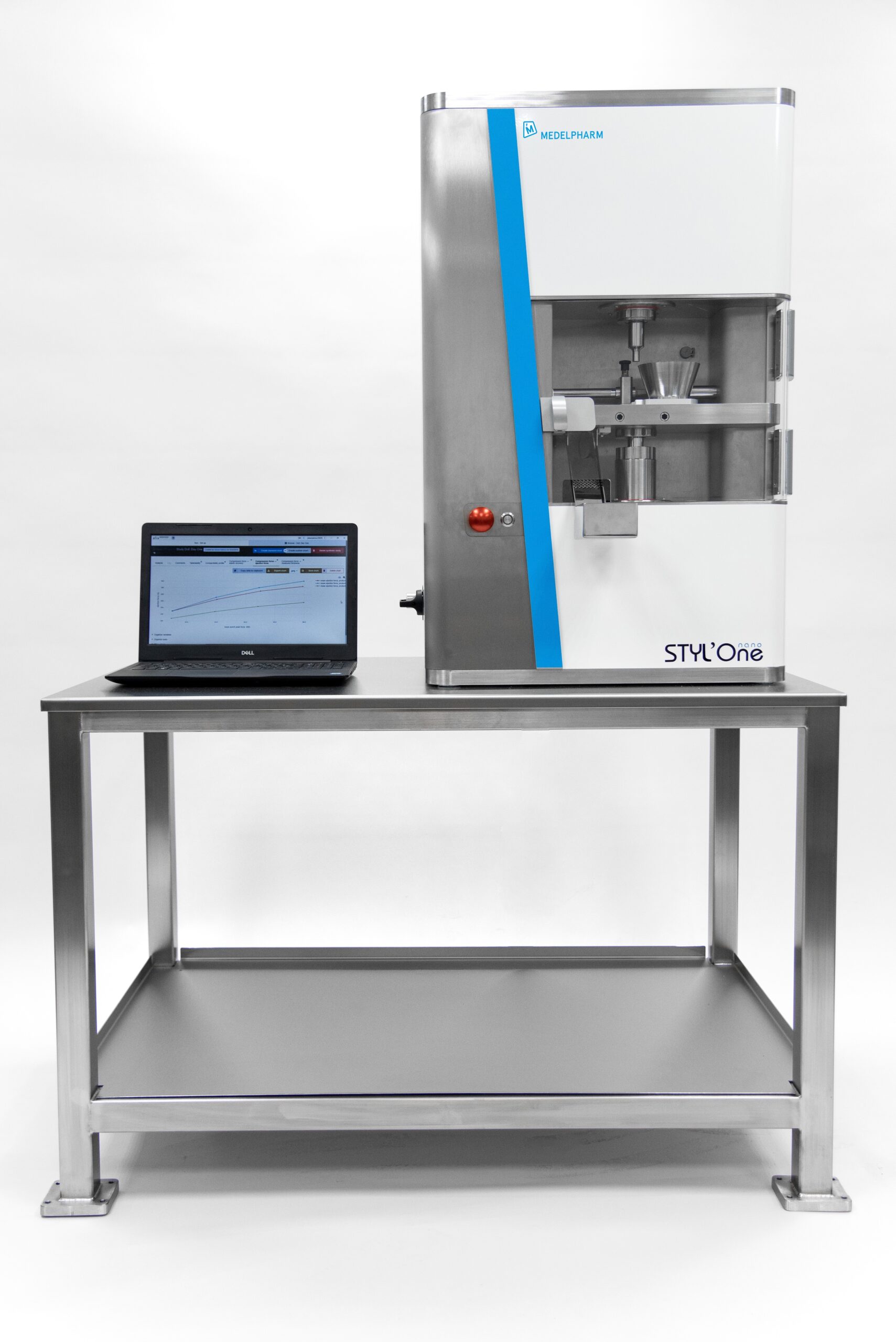

STYL’ONE Nano(R&D Benchtop Tablet Compression Simulator)

The STYL’ONE Nano is a compact benchtop tablet compression simulator that enables efficient tablet characterization with minimal setup and only small quantities of material.

Standard tablet compression profiles compliant with USP <1062> (V-shape / pre- and main-compression / square) are included. It is particularly well suited for collecting and analyzing fundamental data required for early-stage characterization, formulation design, and scale-up to small rotary tablet presses.

X3 MFP (Mid-Range Rotary Tablet Press for Single- and Bi-Layer Tablets)

The X3 is a single-sided rotary tablet press designed for single- and bi-layer tablet production, ideal for scale-up, clinical production, mid-scale manufacturing, and continuous production.

In addition to KORSCH’s established strengths—such as the mixer turret, low noise and vibration levels, integrated control cabinet, and through-the-wall installation—the X3 maintains a highly user-friendly design focused on cleanability, maintainability, and accessibility. By integrating KORSCH’s accumulated know-how, the X3 achieves a more compact footprint and enhanced production capacity, making it an innovative solution for small- to mid-scale production and a showcase of KORSCH’s latest technologies.

X5 MFP (Segmented Turret Rotary Tablet Press for High-Volume Production)

The X5 is KORSCH’s first high-volume rotary tablet press equipped with a segmented turret, supporting the production of single-layer up to three-layer tablets.

While retaining KORSCH’s traditional strengths—such as low noise and vibration levels, an integrated control cabinet, through-the-wall installation, modular cam tracks, and excellent visibility and operability—the segmented turret design increases production capacity by approximately 20–40% compared to conventional turrets.

XT 600 (Double-Sided High-Speed Rotary Tablet Press)

The XT 600 is a high-speed, double-sided rotary tablet press designed specifically for pharmaceutical and food applications.

Incorporating all of KORSCH’s proven technologies for high-volume production, the XT 600 further enhances speed, productivity, operability, and cleanability. Designed for 24/7 unmanned operation, it offers a maximum output of up to 1,000,000 tablets per hour.

With modular cam tracks and an optional conversion kit for bi-layer tablet production, the machine can also produce bi-layer tablets. During bi-layer compression, compression forces for both the first and second layers are individually sampled and monitored, allowing automatic single-tablet rejection if preset compression force limits are exceeded.

Other Special Exhibits

IWK Verpackungstechnik GmbH

| Hall: | 15 |

| Booth: | C20 |

| Exhibit: | Tube Filling Machines & Cartoning Machines |

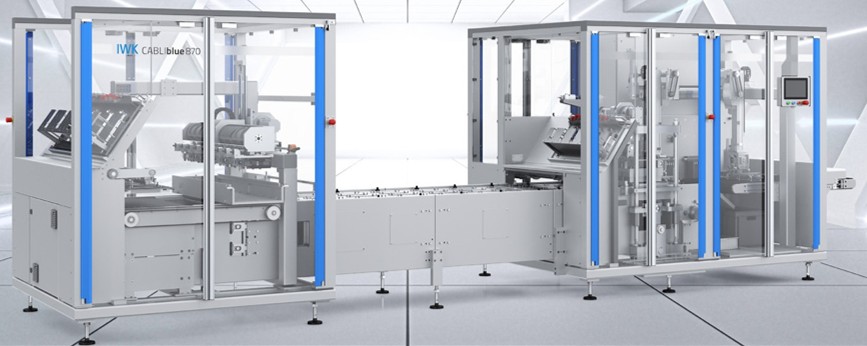

CabliBlue 870 (Blister Packaging System)

CabliBlue 870 is a “PROCESS-SAFE PACKING SOLUTION” that enables completely tool-less format changeovers and supports sustainable packaging using fiber-based materials.

The mono-material blister design eliminates the need for material separation during disposal, while also offering strong marketing appeal through its environmentally conscious packaging concept.

FP18-1 (Tube Filling and Closing System)

The FP18-1 supports a wide range of tube materials, including aluminum, laminate, and plastic tubes. Shorter changeover times contribute to increased production efficiency.

High filling accuracy and excellent sealing performance help minimize product loss.

At the exhibition, we will also introduce the latest developments and new information related to IWK filling systems.

CH4 (Cartoning System)

The CH4 is a servo-motor-driven cartoning system designed for fast and easy format changes, ensuring smooth, stress-free operation.

It integrates two solutions—continuous and intermittent operation—on a single platform.

With high flexibility to accommodate various applications and performance requirements, the CH4 ensures safe carton handling through its advanced packaging technology.

BECOMIX A. Berents GmbH & Co. KG Misch- und Verfahrenstechnik

| Hall: | 15 |

| Booth: | D24 |

| Exhibit: | Vacuum Emulsifying System |

Becomix Emulsification Solutions

Becomix emulsifiers are designed to meet the highest industry requirements. Their performance—particularly the highly regarded Powder Jet technology, which enables powerful and efficient powder induction—contributes significantly to the production of high-quality products.

With a proven track record of over 1,500 installations worldwide, Becomix is a trusted manufacturer serving leading global companies as well as small- and medium-sized enterprises in more than 60 countries.

The portfolio includes vacuum emulsifying systems, dissolving vessels, emulsifiers for lipsticks and suppositories, and inline mixers. Becomix’s production control system, Promas, is also highly valued by customers.

At this exhibition, we are pleased to present the following machines equipped with newly developed technologies.

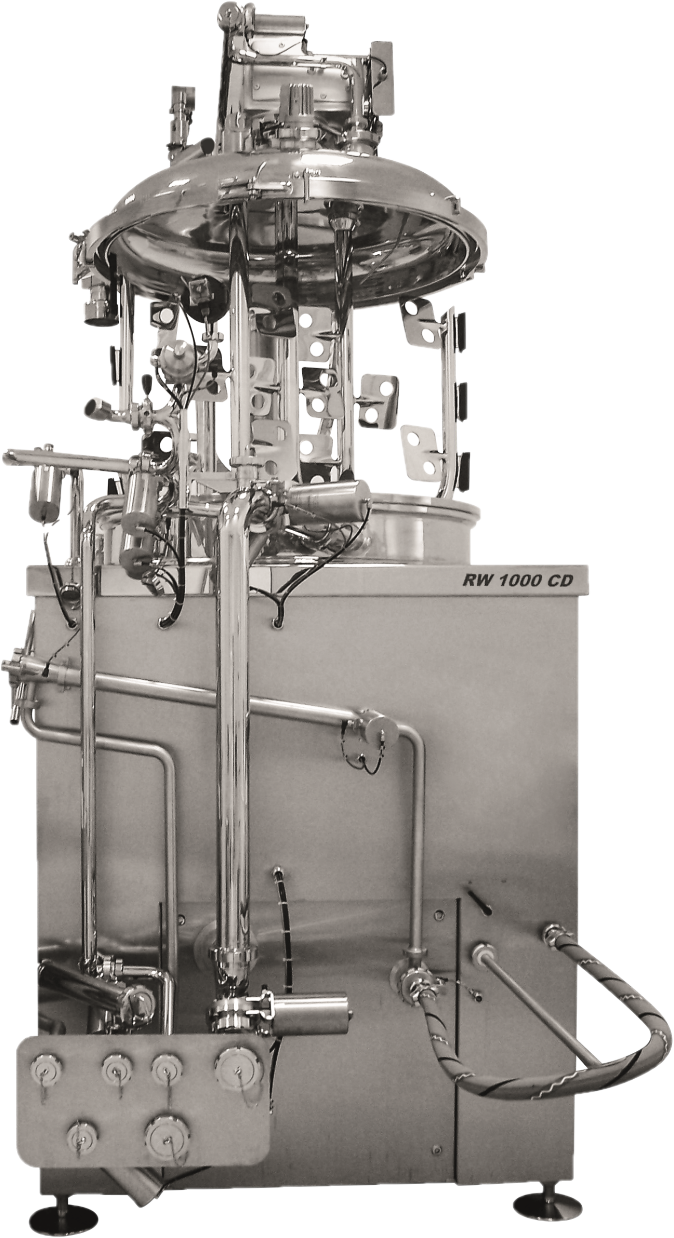

RW600 with Homogenizer X

(Vacuum Emulsifying System with Newly Developed Homogenizer)

The RW600 is equipped with a pressure-resistant / vacuum double-jacketed vessel, a homogenizer, and an anchor agitator. With capacities ranging from 60 to 10,000 liters, it is ideally suited for both pilot plants and full-scale production facilities.

This model features a newly developed, patented homogenizer launched last year.

Compared to conventional powder induction methods, this technology enables powder suction without creating vacuum inside the vessel, preventing powder dispersion, eliminating raw material loss, and contributing to reduced CIP time.

In addition, during powder induction, the homogenizer can be operated in high-shear mode, low-shear mode, or bypassed entirely, allowing dispersion conditions to be optimized according to the characteristics of the raw materials.

RW Mobile Lab Mixer

A laboratory homogenizer designed for R&D applications, supporting capacities from 0.5 to 60 liters. It features a simple and intuitive operating concept. As with production-scale machines, shear intensity can be adjusted from low to high by changing the rotation direction of the homogenizer, enabling precise control tailored to each formulation.

DH Inline Homogenizer

The DH Inline Homogenizer represents a core Becomix technology that enhances the functionality of existing vessels. It enables processes such as heated/cooled emulsification, dilution of high-concentration surfactants, and cooled shampoo production.

Four models are available, covering flow rates from 100 L/min to 2,300 L/min, depending on process requirements.

MV125 (Dissolving Vessel)

The MV125 utilizes Turbo Dissolver (pre-mixing) technology to significantly shorten wax melting and aqueous phase preparation processes, improving batch production efficiency.

It features a pressure-resistant / vacuum double-jacketed vessel with capacities ranging from 60 to 10,000 liters, and optional self-CIP functionality.

Automatic suction feeding for both powders and liquids improves operational efficiency.

Specifications for the turbo dissolver, propeller, and homogenizer can be customized according to raw material properties.

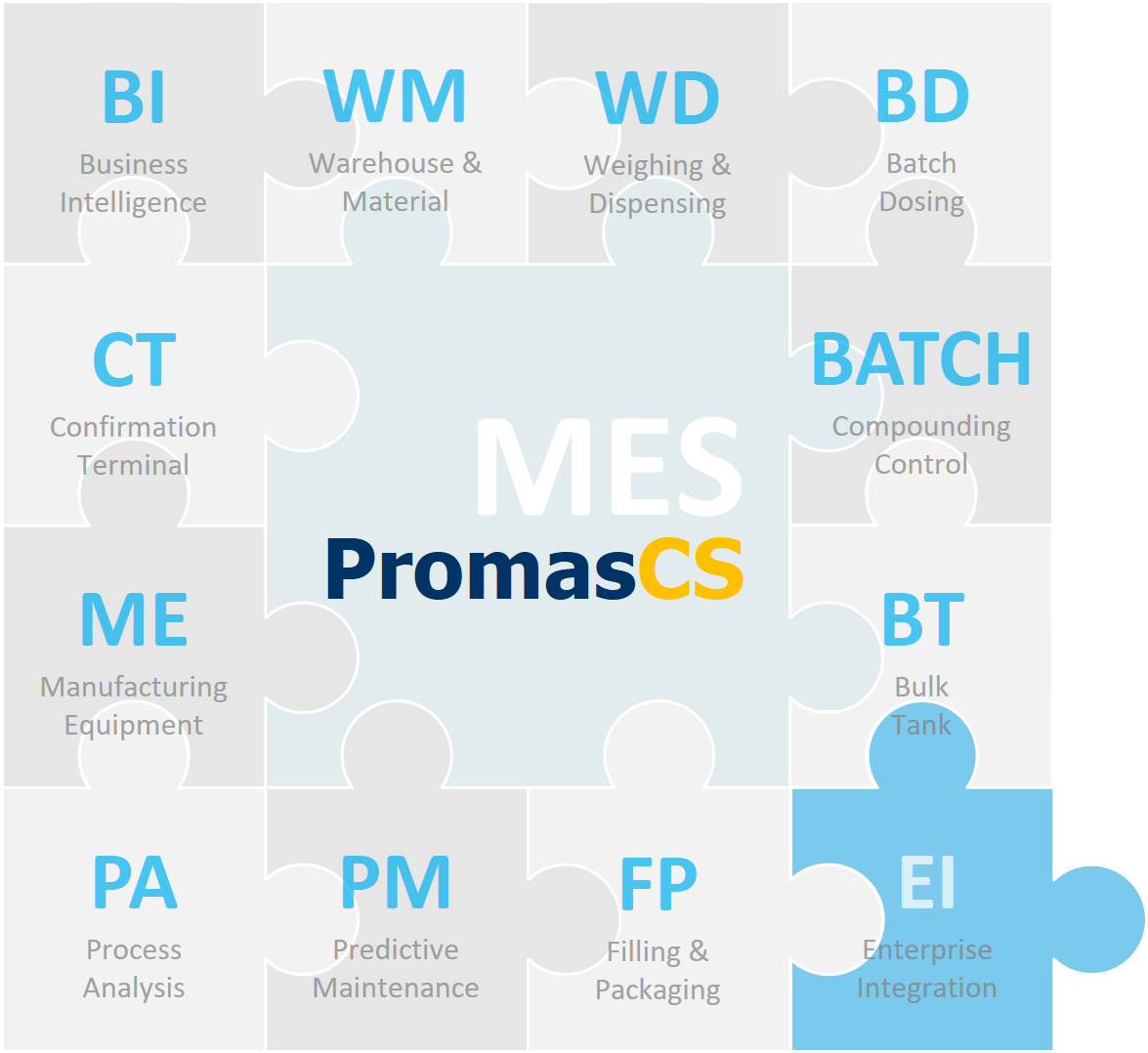

PromasCS MES V7 (Becomix Production Control System)

PromasCS MES V7 enables the creation and execution of automated production and CIP programs for Becomix systems. More than simple scheduling software, it is a Manufacturing Execution System (MES) designed to optimize operation of the entire plant.

Its modular architecture allows customization, including raw material management, integration with weighing systems, process analytics, and maintenance support functions.

KIEFEL GmbH

| Hall: | 8a |

| Booth: | C57 |

| Exhibit: | Thermoforming Machine, Filling Machine |

Mespack S.L.

| Hall: | 6 |

| Booth: | B73 |

| Exhibit: | Pouch Packaging Machine |