We are pleased to announce our participation in the INTERPHEX Tokyo 2025, where we will introduce homogenization, filling, tableting, packaging, and printing machinery for the pharmaceutical and cosmetics industries from 9 European manufacturers.

We would be delighted to welcome you to our booth and invite you to explore our latest products and solutions.

Exhibition Overview

| Date: | July 9(Wed)-11(Fri), 2025 |

| Opening hours: | 10:00~17:00 |

| Venue: | Tokyo Big Sight |

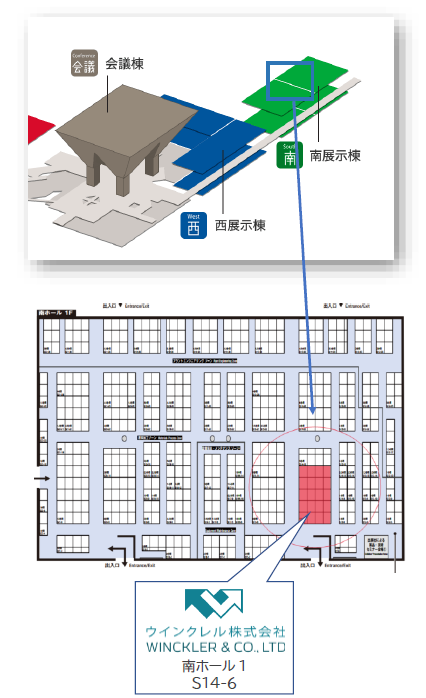

| Hall: | South Hall 1 |

| Booth No.: | S14-6 |

| Registration: | Please register your Entry Badge in advance of your visit. |

Interphex Tokyo 2025 Free Registration

Booth Location

Exhibiting Manufacturer and Machineries

groninger & co. gmbh – Germany

As a leading manufacturer of liquid filling machines for injectables and ophthalmics in the pharmaceutical industry, groninger also develops filling systems for creams, perfumes, and other high-viscosity formulations in the cosmetics sector.

groninger holds a leading track record globally, including in Japan, for filling machines for pre-sterilized nested containers (syringes, vials, cartridges).

LABWORX Series

groninger’s latest benchtop series, LABWORX, consists of four standardized modules (filling with peristaltic or rotary piston pumps, stoppering, and capping). These machines are ideal for R&D, clinical trials, small-batch production, and process development for high-speed lines.

Servo-driven and controlled via tablet or smartphone.

LABWORX Lab Scale Filling Machine

A semi-automatic benchtop machine equipped with a peristaltic pump for filling syringes, cartridges, and vials.

Optional features include vacuum filling, nitrogen replacement, and a load cell for 100% IPC.

LABWORX Lab Scale Stoppering Machine

A semi-automatic benchtop machine for syringes, cartridges, and vial stoppers. Optional vacuum stoppers and sleeve stoppers can be installed.

KORSCH AG – Germany

KORSCH is a specialist in tablet press machines, offering solutions for single-layer, multilayer, core tablets, and chip-in-tablets. Their product range meets high-containment (WIP), Pharma 4.0, and advanced data analysis needs.

XL100 Pro (Compact Rotary Tablet Press)

A tablet press featuring an integrated control panel and simple yet robust design—ideal for product development and small batch production. It provides excellent access to the compression zone, minimizing visible wiring and air tubes for superior operability and cleanability. Its turret is easily replaceable, offering high flexibility. Optional features for early-stage formulation and tableting evaluation are also available, making the XL100 Pro ideal for everything from R&D to small-scale production.

MEDELPHARM – France

MEDELPHARM is a tablet press manufacturer specializing in research and development. Its tablet presses are equipped with software that enables detailed analysis and acquisition of tablet compression data, offering innovative R&D solutions from both mechanical and software perspectives.

STYL’ ONE Evo (R&D Tablet Simulator)

Capable of simulating the compression dynamics of any rotary tablet press. Suitable for early-stage evaluation, formulation, troubleshooting, and scale-up. Supports tablets from single to 5 layers, including core tablets, and complies with USP <1062>. It allows simulation of all essential parameters for evaluation and formulation development.

STYL’ ONE Nano (R&D Benchtop Tablet Simulator)

A compact benchtop tablet simulator requires minimal setup and raw materials for efficient data acquisition.

Standard features include USP <1062>-compliant tablet compression profiles (V-shape, pre/main compression, square). Ideal for scale-up to compact rotary presses, early-stage tableting evaluation, and formulation design.

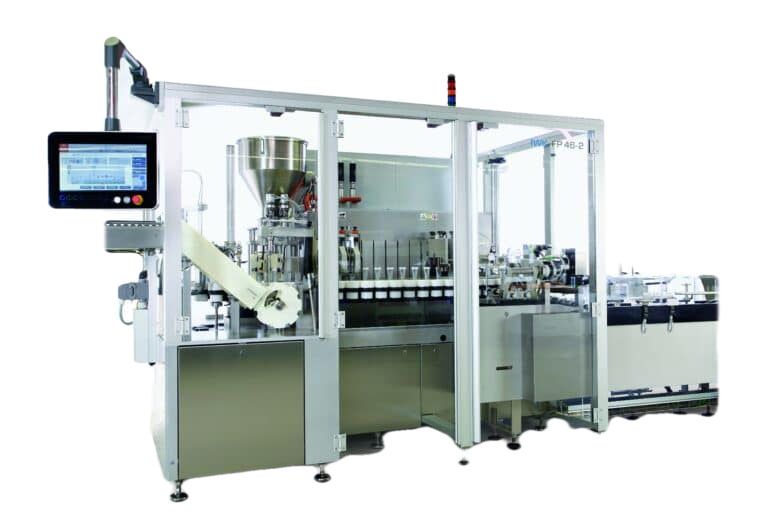

IWK Verpackungstechnik GmbH – Germany

A pioneer in tube filling and packaging since 1893. With numerous patents on core technologies and continuous R&D investment, IWK delivers efficient, high-precision tube filling and packaging machines to the pharmaceutical and cosmetics industries worldwide.

Tube filling machine FP34-1

FP34-1 fills up to 120 tubes/min with stable transport that prevents dents in tubes by stably transporting them using a unique conveyor system. It can handle various tube materials such as aluminum, laminate, and plastic without changing the hot air or saddle folding unit, thereby reducing product changeover time and improving production efficiency. All drives are equipped with servo drives. This enhances positioning accuracy, achieving high filling precision and minimizing product loss.

A.Berents GmbH&Co.KG – Germany

Renowned for high-performance homogenizers under the BECOMIX brand.

Known for features such as the powerful and efficient PowderJet technology for powder suction, BECOMIX contributes to the production of high-quality products with over 2,000 units delivered to leading and mid-sized companies in more than 60 countries.

BECOMIX Vacuum Homogenizing Mixer (RW60CD)

RW 60CD Vacuum Homogenizing Mixer is a multi-mixer ideal for pilot plants and production plants in the cosmetics and pharmaceutical industries, featuring BECOMIX’s unique ability to handle a wide range of products, from high-viscosity to low-viscosity and high-shear to low-shear. By incorporating homogenizers and anchor agitators that are compatible with production equipment, the machine enables easy scale-up and achieves reproducible cleaning performance through CIP specifications.

Getinge Group Japan K.K. – Japan

Getinge is committed to ensuring that every individual and community has access to the best possible care. The company provides products and solutions that improve clinical outcomes and optimize workflows across hospitals and life science facilities. Its core business spans intensive care, cardiovascular surgery, operating rooms, sterile reprocessing, and the life sciences. With approximately 12,000 employees worldwide, Getinge’s solutions are used in over 135 countries.

Getinge Automatic Washing and Drying Device GEW 101210

GEW 101210 is a medium-sized washing device designed for manufacturing areas. It comes standard with GMP-compliant features and a space-saving design with vertical hinged glass doors. With flexible configurations using standard and custom racks, it efficiently and reliably cleans parts and equipment used in biopharmaceutical manufacturing.

Wekerle Machines – Germany

Weckerle Machines is a global leader in filling machines for color cosmetics. In the early 1970s, the company developed and patented the world’s first fully automatic lipstick filling machine. Since then, Weckerle has introduced cutting-edge technologies for a wide range of cosmetic products, including foundations, powders, nail polishes, deodorant sticks, cosmetic pencils, lip balms, glue sticks, and more.

The MM Series offers highly flexible hot filling for various lipstick and lip balm shapes, diameters, and production outputs through modular machine configurations. The lineup supports scale-up from small lab batches to high-volume production with models such as MM 60, MM 180, and MM 360. Tool-less mold change enables efficient and flexible operation.

Note: Sample display only during the exhibition.

mespack – Spain

Headquartered in Barcelona, Spain, Mespack offers one of the industry’s largest portfolios of horizontal and vertical form-fill-seal machines for manufacturing pouches, sachets, stick packs, and water-soluble pods.

With service centers and sales networks across over 90 countries and regions, Mespack ensures rapid delivery of machine parts and minimizes downtime for customers.

Mespack serves major global brands across industries such as food, beverage, pharmaceuticals, chemicals, pet food, confectionery, cosmetics, and personal care consumer products. The company is also committed to sustainability, developing new technologies to reduce raw material usage by enabling the use of recycled or biodegradable materials, contributing to the achievement of the SDGs.

Note: Sample display only during the exhibition.

AISA– Switzerland

AISA operates its own in-house R&D company under its corporate umbrella, strongly supporting customers in their sustainable development initiatives. The company has contributed to the creation of new markets through its advanced patented tube forming technologies such as DecoSeam and Decoplas.

AISA will exhibit its latest paper laminate tube, which reduces plastic use by 75% thanks to its proprietary tube-forming technology. Developed with the goal of enabling recycling alongside paper cartons, the packaging reflects AISA’s collaborative approach to innovation with its clients. AISA has an extensive track record in sustainability, including with monomaterial tube solutions.

Note: Sample display only during the exhibition.

OMSO – Italy

OMSO is a leading manufacturer of container printing machines with over 40 years of experience in the Japanese market. The company is known for its servo series printing machines developed with a deep understanding of user needs, offering solutions for a wide range of applications including tubes, bottles, cups, and caps.

Servo-Assisted Bottle Screen Printer

OMSO introduces its newest screen printing machine for bottles, featuring servo-assisted control that significantly reduces changeover time by minimizing the use of mechanical jigs. The machine adopts the latest LED UV curing system, which helps reduce running costs and contributes to lower CO₂ emissions. This next-generation machine is ideal for an era of accelerating decarbonization.

Note: Sample display only during the exhibition.