Syringe and Vial Filling Machines

Groninger & Co. GmbH, founded in 1980 and based in Crailsheim, Germany, designs and manufactures machines and systems for processing liquid and viscous pharmaceutical products. The company provides machines for processing pharmaceutical products, such as vials and bottles, nested syringes, syringes in bulk, eye drops and nasal sprays, and cylindrical ampules.

At Winckler & Co. we are able to offer Groninger machines compatible with syringes, vials, cartridges and ampules from clinical trial, R & D, scale up to high-speed production line. With an proven track record Winckler & Co. can guarantee excellent results with a safe production process established through delivering small to high output production lines to the Japanese market.

Filling Machine - Testing and small batch

DFVN 1000 series is the smallest filling and stoppering machine by Groninger. It has been designed as a filling and closing machine for presterilized disposable syringes in nest for laboratories, test series and small batches.

This semi-automated stoppering and filling machine offers processes identical to those of a high-output system. There is a clear separation between the manual handling section and the fully automatic production section. The machine supports manual nest handling under laminar flow.

Filling system: Rotary piston pump, peristaltic pump, time pressure, or in combination

Filling Machine - Fully automated production

DFVN 5000 series is a fully automated production system with up to 100% In Process Control capability.

It offers filling and stoppering capability on nested packages with the highest safety and flexibility. Slim and open design allow ideal laminar flow under isolator or RABS environment.

Filling system: Rotary piston pump, peristaltic pump, time pressure, or in combination

Filling Machine - High speed production

DFVN 10000 is a high speed fully automated production system with IPC capability up to 100% objects. This machine is designed for high output facilities under strict production environments.

This machine is the successful, practice-optimized implementation

of the innovative groninger designs for highly aseptic processing of presterilized disposable syringes in nests.

Filling system: Rotary piston pump, peristaltic pump, time pressure, or in combination

Filling Machine - Pre-sterilized, nested syringes processing

The UFVN system is designed to process pre-sterilized syringes and combines all of Groningers expertise into one system. The system transports, fills and closes syringes in nest format.

With its 100% in-process control (IPC), each syringe is individually weighed and assessed.

The UFVN provides the highest possible product quality with production reliability by processing delicate syringes without contact, eliminating the possibility of damage.

Modular filling capping machine

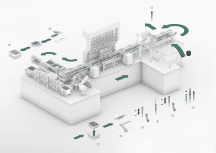

FlexPro 50 is part of the generation of modular filling and capping machines.

The FlexPro 50 is a modular filling and closing system designed to process nested, as well as bulk, syringes, vials and cartridges. It is configurable in any number of layouts, including either isolator or RABs. This modular flexibility offers scalable processing solutions for our customers at reduced cost and shortened delivery times. The FlexPro50 concept is now meeting market requirements for small batch, multiproduct/multiobject filling lines. Franz Ziel's direct injection system greatly shortens VHP cycle time

Filling system: Rotary piston pump, peristaltic pump, time pressure type

Short-lead-time filling and stoppering machine

Flexfill is a filling and stoppering/capping machine specialized for RTU packagings.

By unifying the design, the Flexfill features a shorter delivery time than conventional filling and capping machines.

Although this limits the machine configuration, the design conforms to GMP guidelines, and the reduced lead time to start production is beneficial to all customers.

Compatible filling systems: rotary piston pumps, peristaltic pumps

Benchtop filling and stoppering machine

The newest benchtop machine, LabWorx, consists of four standard models.

Research and development, clinical trial processes, small lot filling, and fast line process development are applications for this series.

LabWorx can be operated via tablet or smartphone.